As electric vehicles (EVs) rapidly scale across global markets, a new challenge — and opportunity — is emerging beyond the road: what happens to EV batteries after their automotive life ends?

While EV batteries may no longer meet the stringent performance requirements of vehicles after 6–8 years, they often retain 70–80% of their original capacity. Instead of being discarded or recycled prematurely, these batteries can be repurposed into second-life energy storage systems.

At the heart of enabling this transformation lies a critical technology: Smart Hybrid Inverters.

In this blog, we will understand how smart hybrid inverters play a critical role in enabling the safe, efficient and scalable reuse of second-life EV batteries across energy storage applications.

Table of Contents

Understanding Second-Life EV Batteries

EV batteries are typically retired from vehicles when their range or peak power capability declines. However, for stationary energy applications such as:

- Residential energy storage

- Commercial backup systems

- Renewable energy buffering

- Microgrids and off-grid installations

These batteries still offer significant usable life.

Second-life batteries provide:

- Lower-cost energy storage

- Reduced environmental impact

- Delayed recycling and material recovery

- Improved ROI across the battery lifecycle

Yet, integrating these batteries safely and efficiently is not straightforward.

Why Second-Life Batteries Need Smart Power Electronics

Unlike new battery packs, second-life EV batteries present unique challenges:

- Non-uniform aging across cells

- Variations in State of Health (SoH)

- Different chemistries and pack architectures

- Inconsistent voltage and capacity profiles

This is where smart hybrid inverters become essential, acting as the intelligence layer between energy sources, batteries and loads.

What Is a Smart Hybrid Inverter?

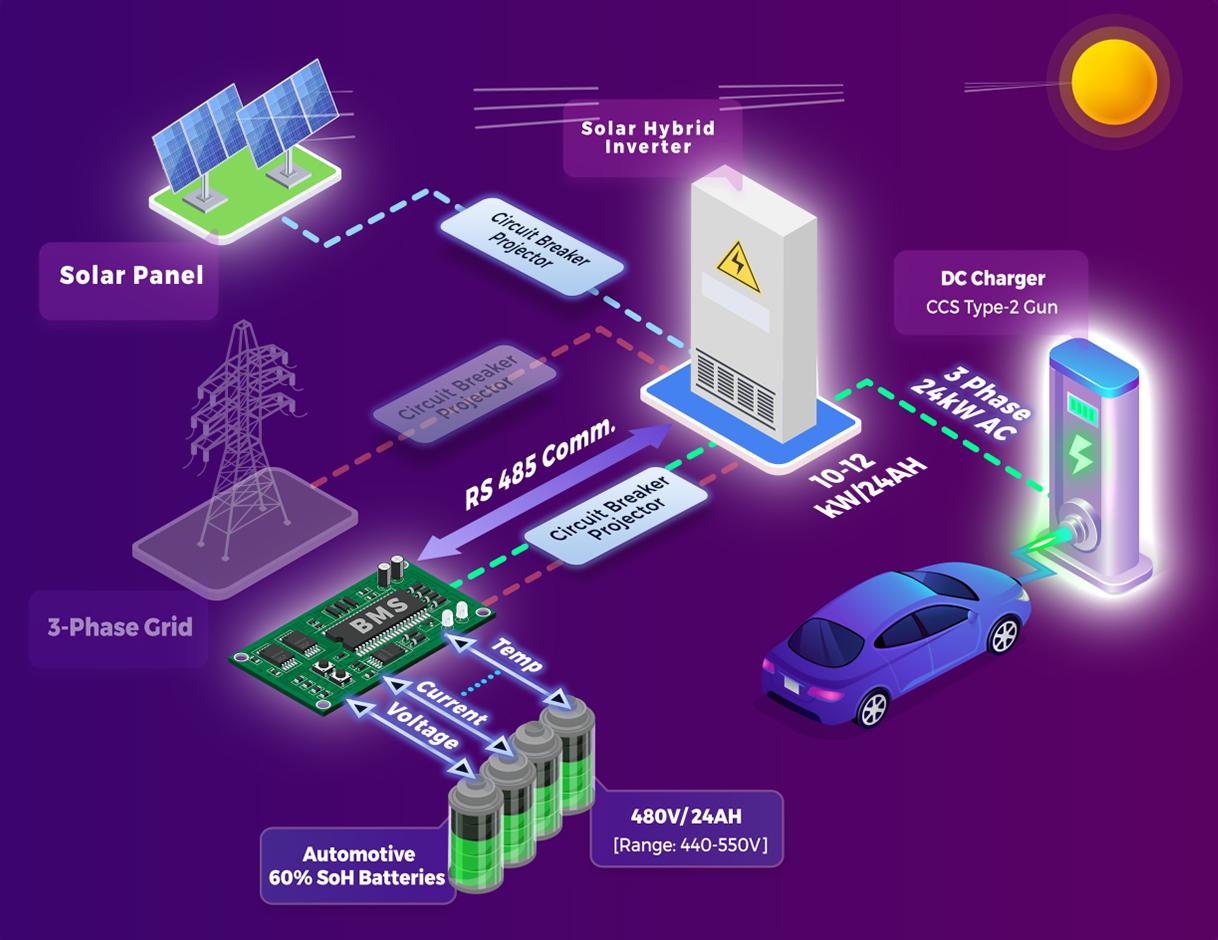

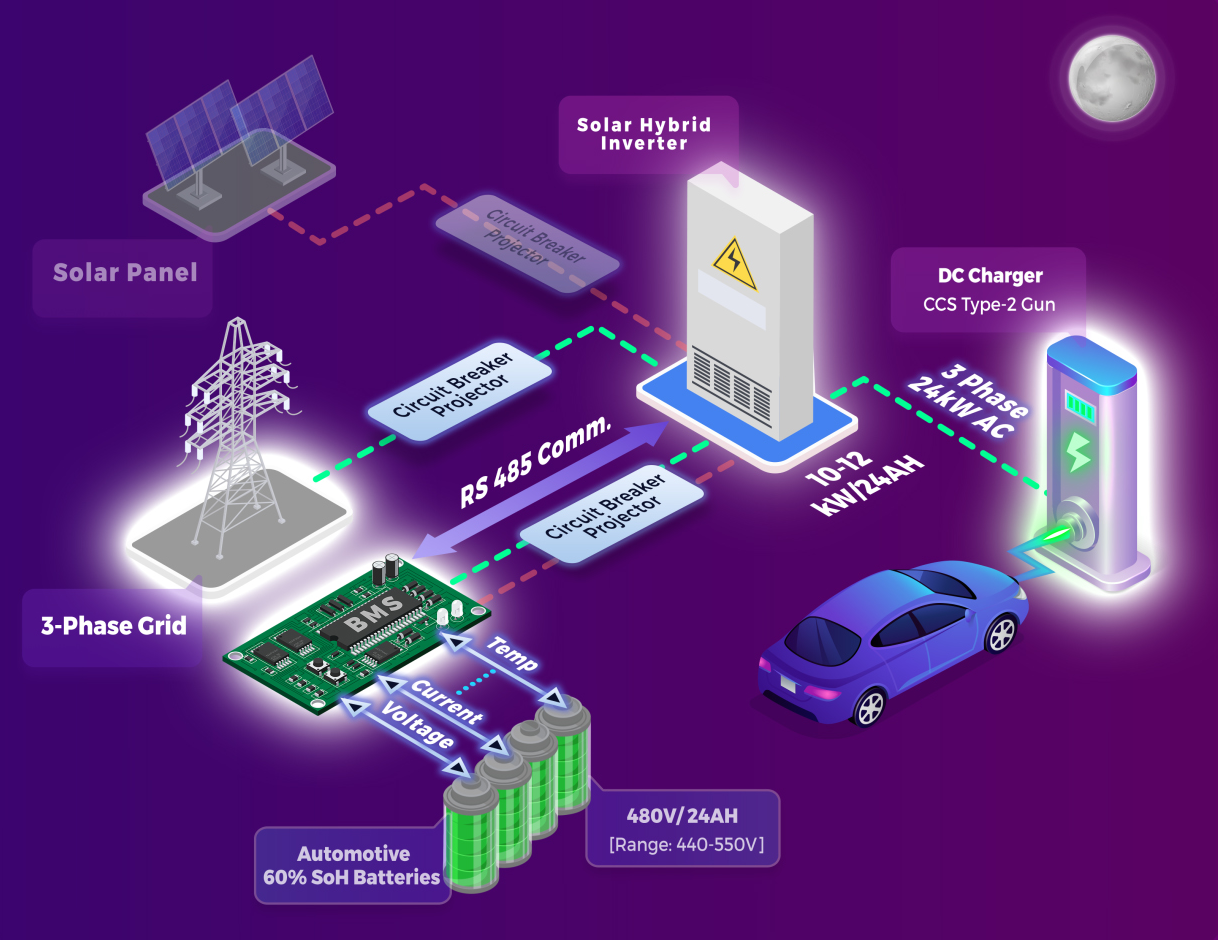

A smart hybrid inverter is an advanced power conversion system capable of managing:

- Solar PV input

- Grid interaction

- Battery energy storage

- Load prioritization

—all through intelligent control algorithms and real-time monitoring.

Unlike conventional inverters, hybrid inverters are bi-directional, allowing energy to flow both into and out of battery systems while dynamically optimizing performance.

How Smart Hybrid Inverters Enable Second-Life Battery Usage

1. Intelligent Battery Management Integration

Smart hybrid inverters work alongside Battery Management Systems (BMS) to:

- Monitor voltage, current, temperature and SoH

- Adapt charging and discharging profiles dynamically

- Isolate weak or degraded battery modules

- Extend remaining battery life

This adaptability is critical when working with aged EV batteries.

2. Voltage and Power Matching

Second-life EV batteries often operate at non-standard voltage ranges.

Hybrid inverters enable:

- Wide DC input voltage support

- Dynamic power derating

- Safe operation despite capacity variations

This allows batteries from different EV platforms to be reused without extensive redesign.

3. Seamless Renewable Energy Integration

When paired with solar or wind systems, hybrid inverters:

- Store excess renewable energy into second-life batteries

- Supply clean power during peak demand

- Reduce grid dependency

This makes second-life batteries ideal for distributed energy storage and behind-the-meter solutions.

4. Grid Support and Energy Optimization

Advanced hybrid inverters support grid-interactive functions such as:

- Peak shaving

- Load shifting

- Time-of-use optimization

- Backup power during outages

Second-life batteries thus become valuable grid assets rather than passive storage.

5. Enhanced Safety Through Software Intelligence

Safety is paramount when dealing with aged batteries.

Smart hybrid inverters ensure:

- Multi-level protection mechanisms

- Thermal monitoring and fault isolation

- Controlled current ramps

- Predictive fault analytics

This software-driven safety approach significantly reduces operational risks.

Key Applications of Second-Life Battery Systems

With smart hybrid inverters, second-life EV batteries can be deployed across:

- Residential energy storage systems (ESS)

- Commercial and industrial backup power

- EV charging stations with buffer storage

- Telecom and data center backup

- Microgrids and rural electrification

These applications demand reliability, adaptability and intelligent control — all enabled by hybrid inverter platforms.

Sustainability and Circular Economy Impact

Repurposing EV batteries aligns strongly with global sustainability goals:

- Reduces raw material mining

- Lowers battery lifecycle carbon footprint

- Supports circular economy models

- Improves overall EV ecosystem economics

Smart hybrid inverters act as the bridge between mobility electrification and energy sustainability.

The Road Ahead

As EV adoption accelerates, the volume of retired batteries will grow exponentially. Unlocking their second life at scale will depend on:

- Advanced power electronics design

- Intelligent control software

- Scalable manufacturing of inverters and ESS

- Standardization and safety compliance

Smart hybrid inverters will play a defining role in ensuring that EV batteries continue delivering value — long after they leave the vehicle.

Conclusion

Second-life EV batteries represent one of the strongest opportunities to build a sustainable and circular energy ecosystem. However, realizing their full potential requires deep expertise in power electronics, battery systems, control algorithms and manufacturing scalability.

VVDN, as a product engineering and manufacturing company, possesses end-to-end technical capabilities across power electronics design, inverter development, BMS integration, embedded software, system validation and mass manufacturing. Our dedicated power electronics engineering teams have deep expertise in this domain and can support the design and manufacturing of smart hybrid inverters and hybrid EV charging solutions tailored for next-generation energy systems.

If you have a project or concept around second-life EV batteries, hybrid inverters or advanced energy storage solutions, feel free to reach out to us at info@vvdntech.com.

We can support you from idea and conceptualization — all the way to production scale.